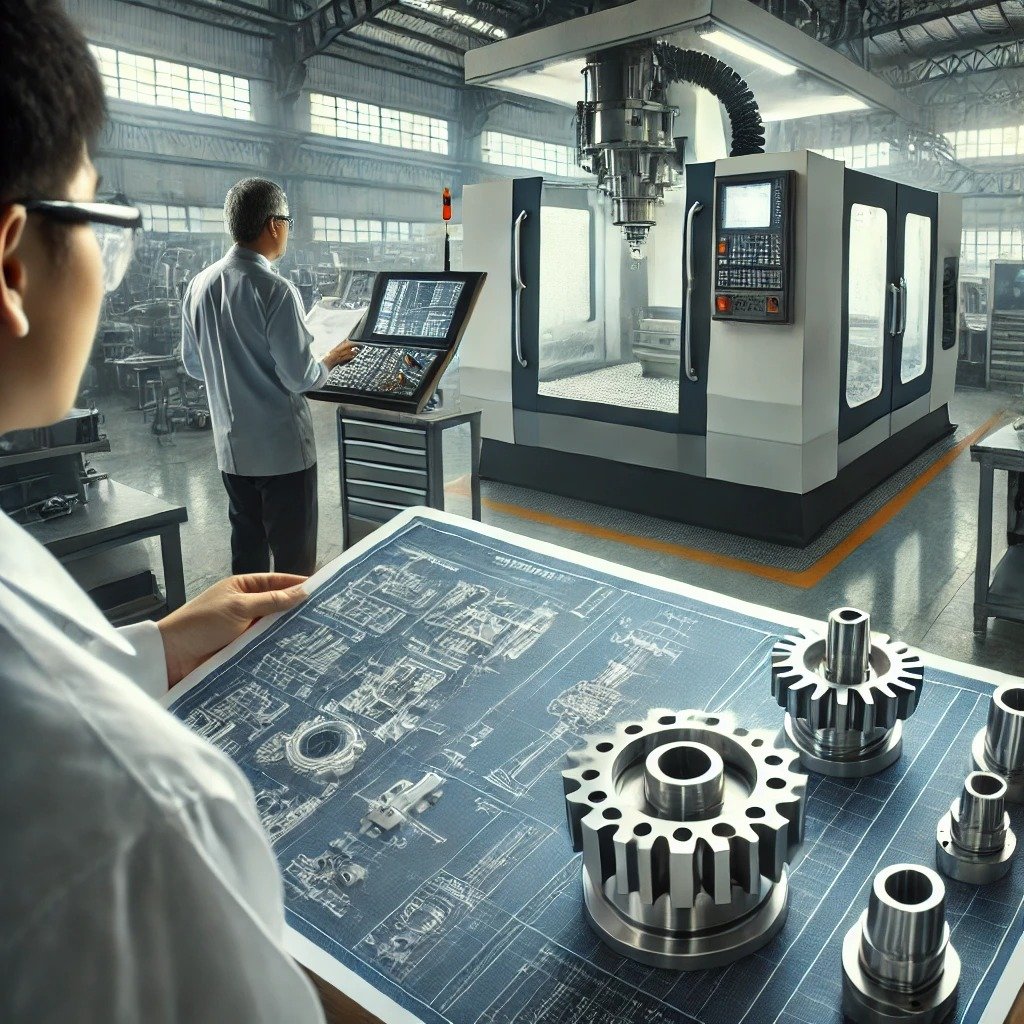

In today’s rapidly evolving industrial landscape, the demand for custom parts manufacturing has surged, driven by the need for specialized components in various sectors such as aerospace, automotive, medical, and electronics. As industries push the boundaries of innovation, the ability to produce tailored parts with precision and efficiency has become a cornerstone of competitive advantage. This is where advanced machining techniques come into play, offering unparalleled accuracy, speed, and flexibility in meeting the unique needs of modern manufacturing.

The Importance of Custom Parts Manufacturing

Custom parts manufacturing is essential for industries that require specific components not available off the shelf. These parts often need to meet stringent specifications regarding size, shape, material, and performance, making their production a complex and highly specialized process. Whether it’s a prototype for a new product or a replacement part for legacy equipment, custom manufacturing ensures that the exact needs of the client are met, down to the smallest detail.

The ability to produce custom parts quickly and accurately can significantly reduce lead times and costs, especially in sectors where time-to-market is critical. Moreover, with the rise of industries such as electric vehicles and renewable energy, the demand for bespoke components that integrate seamlessly with new technologies has never been higher.

Advanced Machining Techniques in Custom Manufacturing

Advanced machining refers to a collection of cutting-edge technologies and processes used to create custom parts with high precision. These techniques go beyond traditional manufacturing methods, leveraging innovations in computer-aided design (CAD), computer-aided manufacturing (CAM), and computer numerical control (CNC) to produce complex geometries and tight tolerances that were previously unattainable.

1. CNC Machining

CNC machining is at the heart of modern custom parts manufacturing. It involves the use of computerized controls to operate machinery, such as lathes, mills, and routers, with extreme precision. CNC machines can produce parts from a wide range of materials, including metals, plastics, and composites, making them versatile tools for custom manufacturing.

One of the key advantages of CNC machining is its ability to produce identical parts consistently, regardless of the complexity of the design. This is particularly important in industries like aerospace and medical, where even the slightest deviation from specifications can lead to catastrophic failures. CNC machining also allows for rapid prototyping, enabling manufacturers to quickly test and refine designs before committing to full-scale production.

2. Additive Manufacturing (3D Printing)

Additive manufacturing, commonly known as 3D printing, has revolutionized custom parts manufacturing by allowing for the creation of complex geometries that would be impossible with traditional subtractive methods. This technology builds parts layer by layer from materials such as plastics, metals, and ceramics, offering unprecedented design freedom and material efficiency.

In custom manufacturing, 3D printing is particularly useful for producing small batches of parts or prototypes, as it eliminates the need for costly tooling and molds. Additionally, 3D printing enables the production of parts with internal structures and features that would be difficult or impossible to achieve with traditional methods, such as lattice structures for lightweight components in aerospace applications.

3. Precision Grinding and Finishing

Precision grinding and finishing processes are critical for achieving the exact dimensions and surface finishes required in custom parts. These processes involve removing material from the surface of a part to achieve the desired shape and finish, often with tolerances in the micrometer range.

Grinding is particularly important in the manufacturing of parts that require high levels of accuracy, such as components for medical devices and aerospace applications. Advanced grinding techniques, such as centerless grinding and surface grinding, allow manufacturers to achieve tight tolerances and smooth finishes that are essential for the performance and longevity of custom parts.

4. Electrical Discharge Machining (EDM)

Electrical discharge machining (EDM) is a non-traditional machining process that uses electrical discharges to remove material from a workpiece. This technique is particularly useful for machining hard materials or intricate shapes that would be difficult to produce with conventional methods.

EDM is commonly used in the production of molds, dies, and complex parts with tight tolerances. The process can create sharp corners, deep cavities, and complex geometries with high precision, making it an invaluable tool in custom parts manufacturing.

Meeting Industry-Specific Requirements

One of the main challenges in custom parts manufacturing is meeting the specific requirements of different industries. Each sector has its own set of standards, regulations, and performance criteria that must be met, often requiring specialized knowledge and expertise.

Aerospace Industry

In the aerospace industry, custom parts must meet stringent requirements for strength, weight, and temperature resistance. Materials such as titanium, Inconel, and aluminum are commonly used, and parts must often withstand extreme conditions while maintaining structural integrity.

Advanced machining techniques, such as CNC machining and EDM, are essential for producing the complex shapes and tight tolerances required in aerospace components. Additionally, additive manufacturing is increasingly being used to produce lightweight parts with complex internal structures that reduce weight without compromising strength.

Medical Industry

The medical industry demands custom parts that meet rigorous standards for biocompatibility, sterility, and precision. Components such as implants, surgical instruments, and diagnostic devices must be manufactured with the highest levels of accuracy to ensure patient safety and effective treatment.

CNC machining and precision grinding are critical for producing the intricate shapes and smooth surfaces required in medical components. Additionally, 3D printing is being used to create custom implants and prosthetics that are tailored to the specific anatomy of individual patients, improving outcomes and reducing recovery times.

Automotive Industry

In the automotive industry, custom parts are often required for high-performance vehicles, electric vehicles, and prototype development. These parts must meet strict requirements for durability, weight, and performance while being produced quickly and cost-effectively.

Advanced machining techniques, such as CNC machining and additive manufacturing, allow automotive manufacturers to produce custom parts with the precision and speed required to stay competitive in the market. The ability to quickly prototype and test new designs also accelerates the development process, enabling faster time-to-market for new vehicles.

The Future of Custom Parts Manufacturing

As technology continues to advance, the future of custom parts manufacturing looks increasingly promising. The integration of artificial intelligence (AI) and machine learning (ML) into manufacturing processes is expected to further enhance the precision, efficiency, and flexibility of custom parts production.

AI and ML can be used to optimize machining parameters, predict tool wear, and improve quality control, leading to higher levels of consistency and accuracy in custom parts manufacturing. Additionally, the development of new materials and machining techniques, such as hybrid manufacturing and nanofabrication, will open up new possibilities for creating custom parts with even more complex geometries and advanced properties.

Moreover, the trend toward digital manufacturing and Industry 4.0 is driving the adoption of smart factories, where interconnected machines and systems can communicate and collaborate to optimize production processes in real-time. This will enable manufacturers to produce custom parts with greater speed and flexibility, meeting the ever-changing demands of the market.

Conclusion

Custom parts manufacturing is a vital component of modern industry, enabling the production of specialized components that meet the unique needs of various sectors. Advanced machining techniques, such as CNC machining, additive manufacturing, precision grinding, and EDM, are essential for achieving the high levels of precision, efficiency, and flexibility required in custom manufacturing.

As industries continue to innovate and push the boundaries of what is possible, the demand for custom parts will only grow. By embracing advanced machining technologies and staying at the forefront of industry trends, manufacturers can ensure that they are well-equipped to meet the challenges of the future and continue to deliver high-quality, custom components that drive progress and innovation.

Leave a Reply